News: LEDs

11 June 2020

Phosphor-free white light-emitting diodes for efficient displays and comms

University of California Santa Barbara (UCSB) in the USA has developed phosphor-free ‘white’ light emitting diodes (LEDs) using semi-polar yellow and blue indium gallium nitride (InGaN) quantum wells (QWs) [Hongjian Li et al, Optics Express, vol.28, p13569, 2020]. Low-cost ‘white’ LEDs generally consist of blue InGaN devices with a phosphor layer that converts some of the generated light into a yellow component.

In addition, the devices demonstrated a natural polarization direction, which could enable more efficient use of back-lights in liquid-crystal displays (LCDs). Further, having the blue and yellow light electrically generated in the UCSB phosphor-free devices improved the modulation bandwidth, giving potential for higher-speed visual light communications (VLC). Phosphor-based light suffers from delays between absorption and emission of light, along with energy losses.

The researchers used semi-polar (20-21) bulk GaN substrates from Mitsubishi Chemical Corp. Atmospheric-pressure metal-organic chemical vapor deposition (AP-MOCVD) was used to create an epitaxial heterostructure: 2μm n-GaN, 30-period 2nm/2nm In0.06Ga0.94N/GaN superlattice, 3nm In0.28Ga0.72N yellow QW, 30nm GaN barrier, 3nm In0.13Ga0.87N blue QW, 30nm GaN spacer, 15nm AlGaN electron-blocking layer, 120nm p-GaN, and 20nm p+-GaN contact. The indium content of the yellow and blue QWs was derived from atom probe tomography (APT).

The use of semi-polar material reduces efficiency-sapping quantum-confined Stark effects (QCSE), where electric fields from the different charge polarizations of the chemical bonds in the heterostructure pulls apart electrons and holes, inhibiting their recombination into photons. The effect has a larger and larger impact as the emission wavelength gets longer.

A range of sub-millimeter and μLEDs were fabricated with 110nm indium tin oxide (ITO) transparent conductor on the p-GaN, and aluminium/nickel/gold metal n- and p-contacts. The LED structures were formed with silicon tetrachloride reactive-ion etch. Silicon dioxide/tantalum pentoxide dielectric omni-directional reflectors were applied by ion-beam deposition, along with an aluminium oxide cap. Atomic layer deposition (ALD) silicon dioxide was used as a 50nm passivation layer for the sidewalls of the devices.

A regular LED with 0.1mm2 effective area achieved a light output power of 0.9mW at 20mA current injection and 3.1V forward voltage. The measurement was made on-wafer and the devices did not have any back-side roughening to enhance light extraction. The researchers say that their experience leads them to believe that backside roughening, along with resin encapsulation and mounting in a silver header, should increase the light output approximately three-fold.

The team also claims that the higher light output and lower forward voltage represent “a significant improvement of performance” over previously reported phosphor-free white semi-polar LEDs.

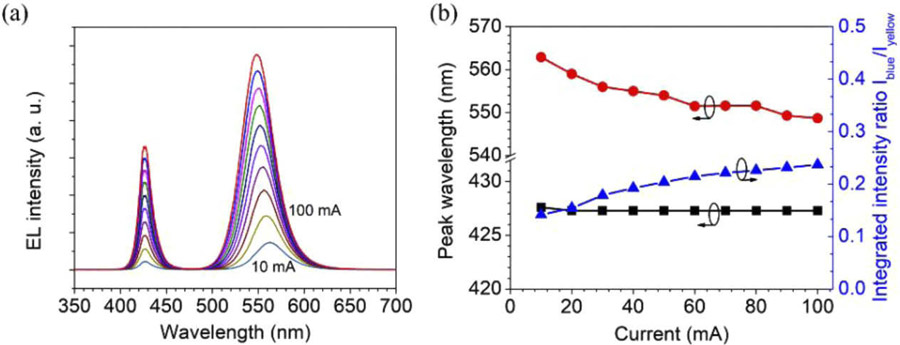

The wavelength spectrum of the devices at 20mA (Figure 1) consisted of two peaks at 427nm (blue) and 560nm (yellow). The full-widths at half maximum (FWHMs) were 18nm and 38nm, respectively. The blue peak showed less than 1nm variation in the 10-100mA range of current injection. By contrast, the yellow peak experienced a blue-shift of 13nm over the same range. Even so, the yellow shift was small compared to that of devices grown in the conventional polar c-direction.

Figure 1: (a) Electroluminscence spectra versus current from 10 to 100mA; (b) peak wavelength of blue and yellow QWs and blue/yellow intensity ratio over the injection current range.

The relative blue content increased as the current increased with the blue/yellow intensity ratio going from 0.14 to 0.24. The researchers suggest that the yellow emission is a combination of electroluminscence from current injection and optical pumping from the blue photons being converted to yellow through photoluminescence.

In terms of Commission Internationale de l’Eclairage (CIE) (x, y) chromaticity, the device emitted light with (0.32, 0.50) co-ordinates at 20mA. The researchers comment: “It is noted that the emission spectrum, CIE and color rendering index (CRI) can be precisely tailored by manipulating the QWs numbers and/or the indium composition in our design.”

The emitted light was also found to be partially polarized, attributed to a strain-related separation of the valence bands in the InGaN layers. In c-plane devices, emitted light is unpolarized. The yellow light was found to be more polarized at 0.41 ratio, compared with 0.34 for the blue radiation. The overall ratio for the monolithic white LED was 0.40. In an LCD, the polarization could be used to reduce losses from the need to input polarized light. With c-plane devices more than half the radiation power is lost in going through a polarizer sheet.

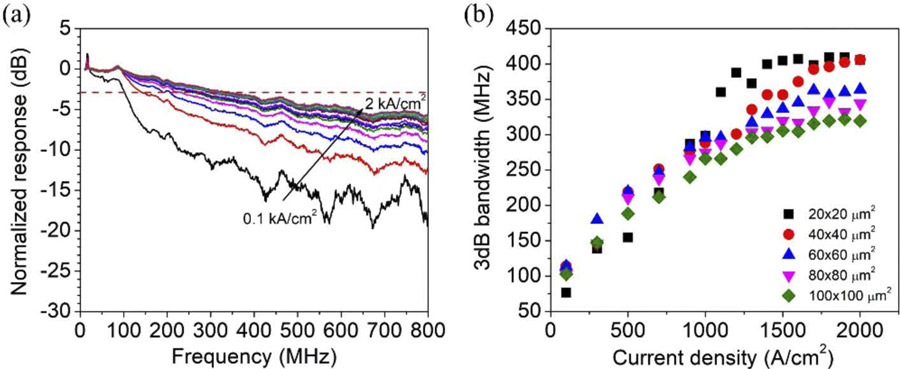

To assess the switching capability of the LEDs for VLC applications, micro-devices were used to enable high current densities. The 3dB modulation bandwidth was found to increase with current density (Figure 2). The researchers attribute the improvement to “screening of built-in electric field and the reduced carrier lifetime by a higher injected carrier density”.

Figure 2: (a) Frequency response of square μLED with 60μm sides, and (b) 3dB modulation bandwidth versus current density for different size square μmLEDs.

Also, smaller devices had slightly higher bandwidth. Square devices with sides of 20μm and 40μm demonstrated bandwidths of up to 410MHz. Better performance has been achieved with the non-polar m-plane blue LEDs, but the team expects “optimizing the barriers/wells thickness and the number of blue/yellow QWs” to improve the bandwidth of the yellow/blue LEDs. The researchers point out that there is generally a trade-off between efficiency and modulation bandwidth.

The team comments: “it is promising to achieve a high luminous efficiency in monolithic white LEDs by integrating blue and yellow QWs directly grown on semi-polar (20-21) GaN substrate in one growth.”

White LEDs InGaN GaN AP-MOCVD ALD

www.osapublishing.org/oe/abstract.cfm?uri=oe-28-9-13569

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.