25 February 2021

Detecting and Classifying Defects in Semiconductor Manufacturing via Atomic Force Microscopy

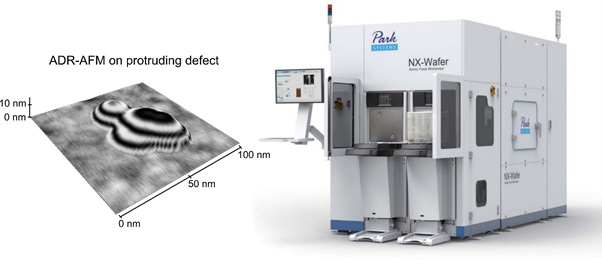

Automatic defect review with atomic force microscopy visualizes defects in three dimensions with nanometer-resolution and therefore qualifies as ideal technique for the semiconductor industry where imaging nanoscale devices is an integral part of the manufacturing process.

Advances in lithographic processing allows for the production of ever smaller semiconductor devices. With decreasing device sizes, nanometer-sized defects on the wafer substrates can already limit the performance of the devices. The detection and classification of these defects requires characterization methods with a resolution in the nanometer-range. Due to the diffraction limit of visible light, the conventional automatic optical inspection (AOI) cannot achieve a sufficient resolution in that range, which impairs quantitative imaging and consequent classification of defects. The automatic defect review (ADR) with atomic force microscopy (AFM), on the other hand, visualizes defects in three dimensions with the nanometer-resolution customary for AFM. Thereby, ADR-AFM reduces uncertainties in the defect classification and qualifies as ideal technique for defect review in the semiconductor industry.

Defect inspection and review

As semiconductor devices are getting smaller and smaller in accordance with Moore’s law, the size of the defects of interest (DOI) decreases as well. DOI are defects that potentially reduce the performance of semiconductor devices and are therefore of interest to process yield management. The decreasing size of the DO is a challenge for the defect analysis: Suitable characterization methods must be able to image defects non-invasively with high lateral and vertical resolution in a two-digit or single-digit nanometer-range.

Traditionally, defect analysis in the semiconductor industry consists of two steps. The first step, called defect inspection, utilizes fast imaging methods with a high throughput but low resolution, such as scanning surface inspection systems (SSIS) or AOI. These methods can provide maps with the coordinates of defect positions on the wafer surface. However, due to their lower resolution, AOI and SSIS give insufficient information when characterizing nanometer-sized DOI and therefore rely on high-resolution techniques for the defect review in the second step. For this second step, high-resolution microscopy methods, like transmission or scanning electron microscopy (TEM and SEM) or AFM, image smaller areas of the wafer surface to resolve the DOI by using the defect coordinate maps from defect inspection. Utilizing the coordinate maps from AOI or SSIS minimizes the scan area of interest and thus the measurement time of the defect review.

While the electron beam of SEM and TEM potentially inflicts damage onto the wafers, AFM can scan surfaces non-invasively, if a non-contact measurement mode is employed. Furthermore, only AFM is capable to image defects with a high vertical resolution in addition to a high lateral resolution. Therefore, AFM provides quantitative three-dimensional information about defects required for reliable defect classification.

Atomic force microscopy

By mechanically scanning surfaces with a nanometer-sized tip on the end of a cantilever, AFM achieves the highest vertical resolution among conventional imaging methods. Aside from contact mode, AFM can be operated in a dynamic measurement mode, in which the cantilever oscillates above the surface. Here, changes in the oscillation amplitude or frequency provide information on the sample topography. This contact-free AFM mode ensures non-invasive imaging of wafer surfaces with high lateral and vertical resolution. Due to recent developments in automated AFM, the application of AFM spread from academic research to industry sectors such as hard disk manufacturing and semiconductor technology. The industry started to focus on the versatility of AFM and its ability to non-invasively characterize nanostructures in three dimensions. Hence, AFM is evolving into a next-generation inline measurement solution for defect analysis.

Automatic defect review with atomic force microscopy

One of the biggest challenges of AFM-based defect review is the transfer of defect coordinates from AOI to AFM. Originally, the user manually marked defect positions on an optical microscope in an additional step between AOI and AFM, and subsequently searched these positions in the AFM. However, this additional step was time-consuming and lowered the throughput significantly. The automatic defect review with AFM, on the other hand, imports the coordinates of defects from the AOI data. The import of defect coordinates requires an accurate alignment of the wafer as well as the compensation of stage errors between AOI and AFM. An optical analysis tool (e.g. candela), with higher position accuracy than AOI can reduce the stage error in a quick intermediate calibration step. The following ADR-AFM measurement consists of a large-scale survey scan at the given defect coordinates, a high-resolution image of the defect, and the defect classification. Because of the automation, the user does not have to be present during the measurement and the throughput increases by up to an order of magnitude. To maintain the nanometer-range tip radius and thus a high resolution for multiple subsequent scans, ADR-AFM uses a non-contact dynamic imaging mode. Thereby, ADR-AFM prevents tip wear and ensures a quantitative defect review.

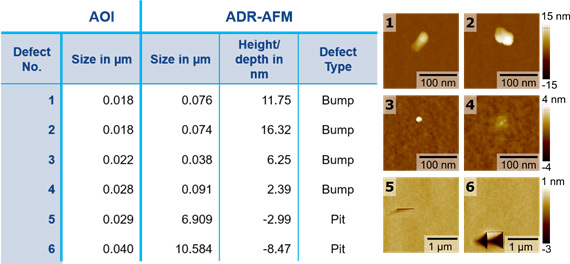

Figure 1: Direct comparison of the defect sizes determined with AOI and ADR-AFM in the table on the left side. The according AFM topography scans of all six defects are shown on the right. Protruding defects are named bump, indenting defects are named pit.

Comparing AOI and ADR-AFM

The results of a defect review with AOI and ADR-AFM on the same nanometer-sized defects are compared in Figure 1. While AOI estimates the size of the defects based on the intensity of scattered light, ADR-AFM directly images defects by mechanically scanning the surface: In addition to their lateral size, ADR-AFM measures the height or depth of the defects and thus allows differentiating between protruding "bump" and indenting "pit" defects. The visualization of the three-dimensional shape of the defects ensures a reliable defect classification, which cannot be achieved via AOI.

When comparing the defect sizes determined via AOI and ADR-AFM, it shows that the values estimated by AOI strongly differ from the defect sizes measured via ADR-AFM. For bump defects, AOI consistently underestimated the defect size by more than half. This underestimation becomes evident especially for defect 4. Here, AOI gave a size of 28 nm – roughly one third of the size determined by ADR-AFM with 91 nm. However, the largest deviations between AOI and ADR-AFM were observed for measurements on the "pit" defects 5 and 6. AOI underestimated defects with sizes in the micrometer-range by more than two orders of magnitude. The comparison of the defect sizes determined with AOI and ADR-AFM clearly showed that AOI alone is insufficient for the imaging and classification of defects.

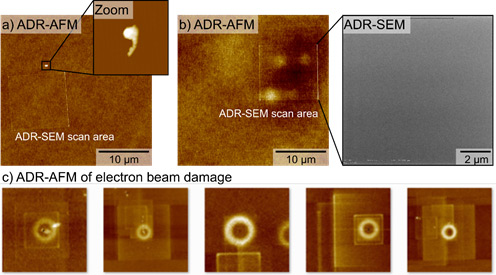

Figure 2: Comparison between ADR-AFM and ADR-SEM, a)AFM image of bump defect missed previously by ADR-SEM. The ADR-SEM scan area is visible as rectangle in the AFM topography scan. b) Imaging of a defect with a low height (0.5 nm), which was not resolved by ADR-SEM. c) Examples of electron beam damage on the wafer-surface following ADR-SEM measurements, visible as rectangular areas around the defects.

Comparing ADR-SEM and ADR-AFM

Instead of ADR-AFM, it is also possible to use ADR-SEM for high-resolution defect review. ADR-SEM conducts the automatic defect review based on DOI coordinates from the AOI data via an SEM measurement, during which a high-energy electron beam scans the wafer surface. While SEM offers a high lateral resolution, it generally cannot provide quantitative height information about the defects.

To compare the capabilities of ADR-SEM and ADR-AFM, the same areas of a wafer were first imaged by ADR-SEM followed by an ADR-AFM measurement (Figure 2). The AFM images showed a changed wafer surface at the position of the ADR-SEM scan, visible in Figure 2a as rectangle in the AFM topography. Due to the visibility of the ADR-SEM scan area in ADR-AFM, Figure 2a illustrates that ADR-SEM missed a protruding defect, which was located just above the SEM scan area. Furthermore, ADR-AFM with its high vertical resolution exhibited a sufficient sensitivity to detect surface defects with a height as low as 0.5 nm. These defects could not be imaged by ADR-SEM due to the lack of vertical resolution (Figure 2b). Additionally, Figure 2c highlights the risk of electron beam damages on wafers by summarizing examples of changes on the sample surface caused by the high-energy electron beam. The ADR-SEM scan areas can be recognized in the ADR-AFM images as rectangles surrounding the defects. In contrast, non-invasive imaging and the high vertical resolution make ADR-AFM ideally suited as characterization technique for defect review.

Conclusion

With the ever-decreasing size of semiconductor devices in modern technology, AFM has gained importance in the semiconductor industry as a high-resolution and non-invasive analysis method for defect review. The automation of AFM measurements simplified and sped up the previously time-consuming workflow for AFM in the defect characterization. The progress in AFM automation was the basis for the introduction of ADR-AFM, in which the defect coordinates can be imported from prior AOI measurements and the subsequent AFM-based characterization does not require the presence of a user. Therefore, ADR-AFM qualifies as an inline methodology for defect review. Especially for defect sizes in the one- or two-digit nanometer-range, ADR-AFM complements conventional AOI, with the high vertical resolution of AFM facilitating a reliable and three-dimensional defect classification. The non-contact measurement mode ensures non-invasive surface characterization and prevents wear of the AFM tip, which guarantees that the high resolution is maintained in many consecutive measurements.

AUTHORS:

AUTHORS:

Sang-Joon Cho, Vice President and director of R&D Center, Park Systems Corp.

Ilka M. Hermes, Principal Scientist, Park Systems Europe