News: LEDs

4 November 2021

AlN passivation for InGaN micro-LEDs

Fudan University in China has reported improved efficiency for indium gallium nitride (InGaN) micro-scale (blue) light-emitting diodes (micro-LEDs) from using aluminium nitride (AlN) passivation [Dingbo Chen et al, Optics Express, p36559, v29, 2021]. AlN passivation has previously been deployed in power GaN applications, and for p-GaN LED contacts, but not so far for micro-LED sidewalls, according to the team.

Passivation of mesa sidewalls is critical in micro-LEDs since activity there increases in relative importance as scales reduce. Dangling bonds and surface damage from etch processes lead to non-radiative recombination centers, and also increase surface conductivity, leading to leakage currents.

The researchers see future opportunities arising from combined micro-scale light emission/detection devices for intelligent display and communication systems.

AlN applied using atomic layer deposition (ALD) is more compact than the more common plasma-enhanced chemical vapor deposition (PECVD) silicon dioxide (SiO2). In fact, PECVD SiO2 does not provide sufficient surface coverage in very small devices.

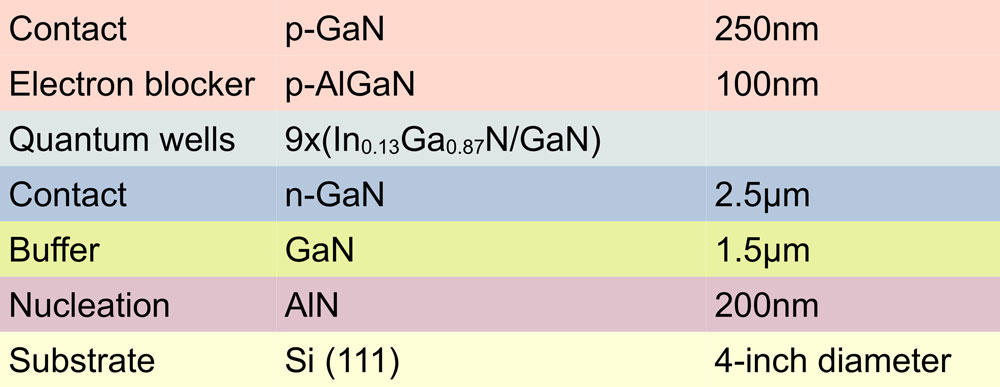

Figure 1: Epitaxial structure.

The micro-LED structure (Figure 1) was grown by metal-organic chemical vapor deposition (MOCVD) on silicon (Si). The p-GaN contact was activated by annealing at 700°C for 10 minutes in nitrogen.

Device fabrication began with forming the p-side Ohmic contact and transparent current spreader by using electron-beam evaporation and annealing of 5/5nm nickel/gold. The 800nm-high device mesa was sculpted using plasma and wet etch with patterning from ultraviolet photolithography.

The sidewalls were passivated with 30nm AlN from plasma-enhanced ALD. The structure was then covered with PECVD SiO2.

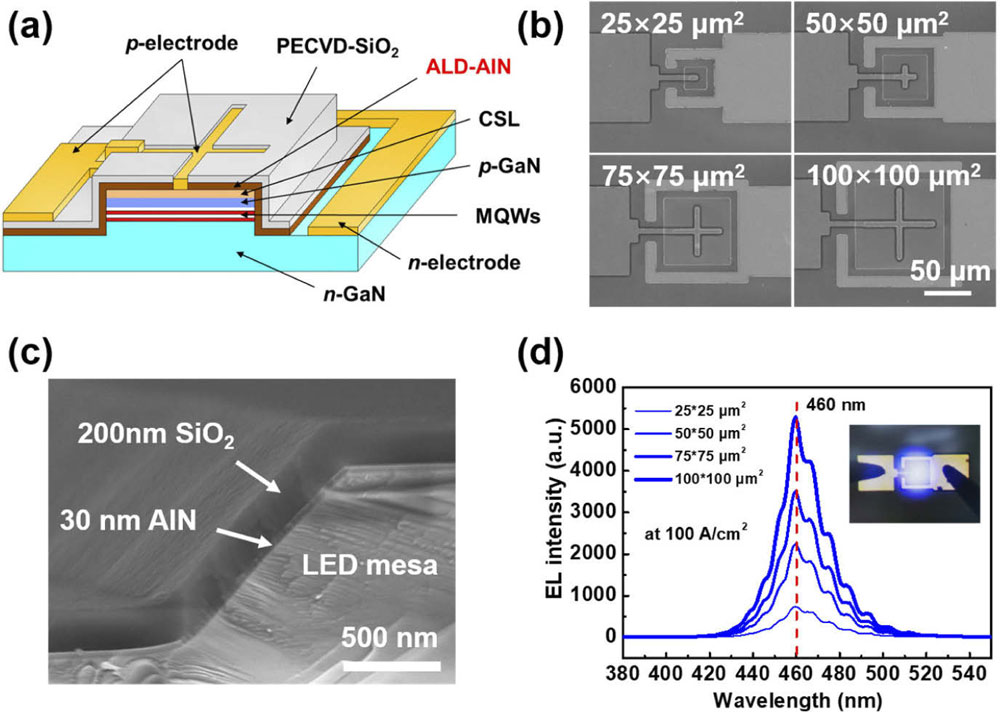

The device (Figure 2) was completed by wet etch through the SiO2/AlN and application of titanium/gold electrodes. The peak electroluminescence wavelength was found to be 460nm.

Figure 2: (a) Micro-LED design; (b) scanning electron microscope (SEM) images of fabricated micro-LEDs with different sizes; (c) SEM cross-section of passivated sidewall of micro-LEDs; (d) electroluminescence characteristics of micro-LEDs at 100A/cm2. Inset: microscope image of 50μmx50μm device.

The researchers compared the AlN passivation with aluminium oxide (Al2O3) passivation produced from ALD with oxygen replacing ammonia (NH3) as precursor. In both cases, trimethyl-Al was used as the metal-organic precursor. Al2O3 passivation has previously been found to improve the performance of InGaN micro-LEDs.

The turn-on performance improved as the devices became smaller with the turn-on voltage reducing. “This effect is explained by improved thermal and current spreading inside smaller devices,” the team comments.

The AlN passivation reduced the leakage current below turn-on by up to two orders of magnitude relative to the Al2O3 device. The minimum ideality factor (d(ln I)/dV-kT) was measured just above 2V bias. The AlN passivation ideality minimum was 1.6; that of Al2O3 was 2.5. Ideality above 2 is indicative of trap-assisted tunneling and carrier leakage, the researchers point out.

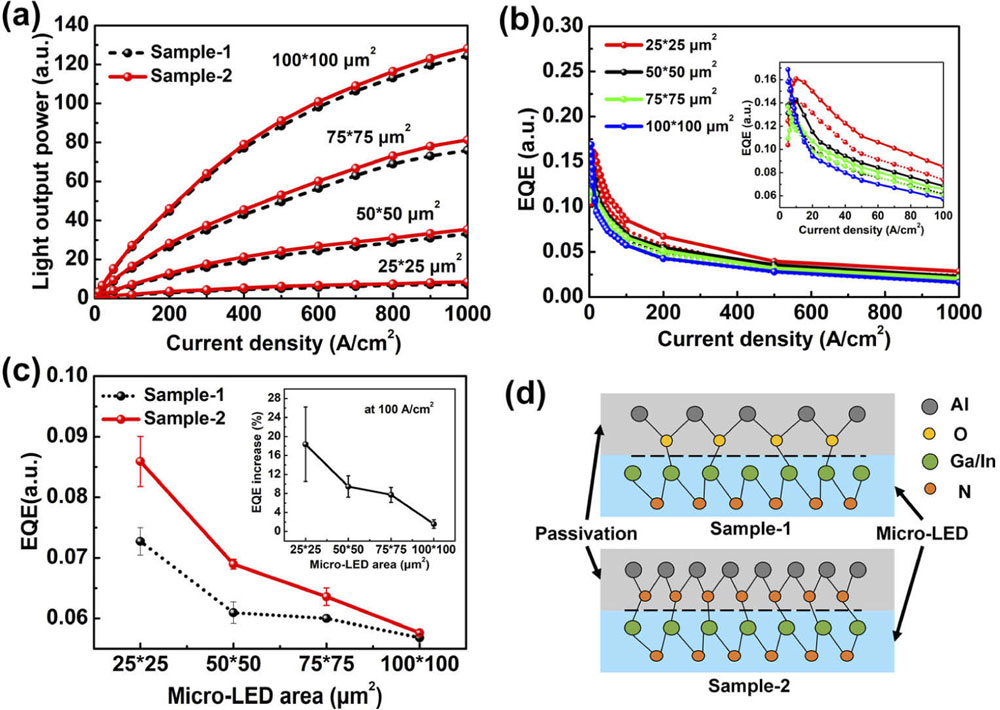

The light output power (LOP) had similar performance relative to current density for both device types (Figure 3). However, the reduced voltage needed to achieve a given current increased the external quantum efficiency (EQE) of the AlN passivated devices.

Figure 3: (a) LOP and (b) EQE versus current density characteristics of micro-LED with different passivation and sizes. Inset: EQE in 0-100A/cm2 range. Dashed lines represent Sample-1 (Al2O3 passivation) and solid lines represent Sample-2 (AlN). (c) Comparison of EQE at 100A/cm2. Inset: EQE increase of sample-2 relative to sample-1 versus micro-LED sizes. (d) Ball and stick models for passivation interfaces.

Both micro-LEDs suffered severe efficiency droop. Smaller devices had better EQE performance except at very low current, less than 20A/cm2. For the smallest 25μmx25μm devices, using AlN passivation improved the peak EQE by 18.3% over Al2O3. The improvement in 100μmx100μm LEDs was just 1.6%.

The researchers suggest that the improved AlN passivation results from a better lattice matching with GaN resulting in fewer dangling bonds at the AlN/GaN sidewall interface, relative to Al2O3/GaN.

The team also studied the inverse of light emission – self-powered 0V-bias photodetection. The response spectrum was found to lie mainly in the wavelength range 200-500nm. The peak response was around 360nm, ultraviolet. The EQE of the smallest 25μmx25μm device was about an order of magnitude smaller (~0.05) than the other sizes (0.25-0.4). The AlN passivation, however, gave a 57.7% improved EQE over Al2O3 for this smallest micro-LED structure. The improvement for other sizes were: 26.8% for the 50μm square mesas; 11.7%, 75μm; and 3.2%, 100μm.

The researchers suggest that the poor performance of the smallest form factor could be due to “the relatively small proportion of the light absorption area of the device of this size”.

AlN AlN passivation InGaN InGaN micro-LEDs ALD PECVD

https://doi.org/10.1364/OE.439596

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.