News: LEDs

16 September 2021

Increased current for red InGaN μLEDs

King Abdullah University of Science and Technology (KAUST) in Saudi Arabia has reported indium gallium nitride (InGaN) red micro-sized light-emitting diodes (μLEDs) aimed at meeting the color and power requirements of LED-based displays [Zhe Zhuang et al, Photonics Research, v9, p1796, 2021]. In particular, the researchers compared the color performance of red, green and blue (RGB) InGaN μLED arrays with that required by the International Telecommunication Union Radiocommunication Sector (ITU-R) Recommendation BT.2020 (Rec.2020), ‘Parameter values for ultra-high definition television systems for production and international programme exchange’.

Although blue and green InGaN LEDs are reaching commercialization, the red sector is still very much “in development” with red InGaN LEDs generally suffering from very low efficiency and output power, compared with devices based on aluminium gallium indium phosphide (AlGaInP) technology. However, the AlGaInP LED performance does not scale well to the micro-level. This is attributed to material problems, in particular high surface recombination velocities and longer carrier diffusion lengths. As devices become smaller, surface effects come to dominate. Surface carrier recombination tends to be non-radiative, sapping output power. By contrast, the performance of InGaN red μLEDs has been found to be only slightly impacted by scaling to the micro-level.

Displays based on mixing RGB light from μLEDs is desired from the perspectives of fast response, long lifetime, high brightness level, and low energy consumption.

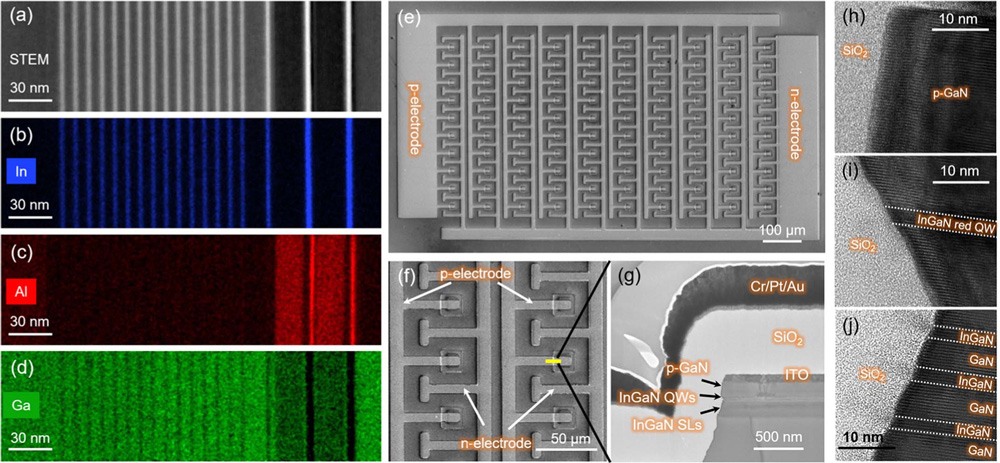

The KAUST red InGaN structure was grown by metal-organic vapor phase epitaxy (MOVPE) on patterned sapphire at 100kPa pressure. The active region consisted of two red-emitting quantum wells (QWs) and one blue-emitting quantum well. The 24nm barriers between the wells used a multi-layer AlN/GaN/AlGaN/GaN structure in an effort to compensate for strain imbalances. The presence of aluminium (Al) in the barrier also inhibited indium evaporation from wells during high-temperature growth. A 15-period InGaN/GaN superlattice (SL) was placed under the active region.

Figure 1: (a) Cross-sectional scanning transmission electron microscopy (STEM) image of red InGaN LED structures. (b)–(d) Energy-dispersive x-ray spectroscopy (EDS) elemental mappings of In, Al and Ga atoms in InGaN QWs and SLs. (e) Top-view and (f) high-resolution scanning electron microscopy (SEM) images for red μLED array. (g) Cross-sectional TEM image of single μLED. (h)–(j) Cross-sectional high-resolution TEM (HRTEM) images of interfaces between nitride materials and SiO2.

The μLEDs were fabricated with indium tin oxide (ITO) as a transparent conductor on the p-side on the device (Figure 1). The ITO layer was annealed in a two-step process. Then the 17μmx17μm device mesa was plasma etched using plasma-enhanced chemical vapor deposition (PECVD) silicon dioxide (SiO2) as a hard mask. The mesa sidewalls were treated with tetramethylammonium hydroxide (TMAH) wet-etching to remove surface damage from the plasma etch process.

The SiO2 hard mask residue was removed with buffered oxide etch and replaced with a new layer of PECVD SiO2 as a sidewall passivation layer and electrical isolation. The n- and p-electrodes consisted of chromium/platinum/gold connected through the SiO2. The devices were connected in 10x10 arrays, using the same metal combination as for the electrodes. Green and blue 10x10 structures were also fabricated using commercial LED wafers.

The turn-on voltage was around 2V, while there was quite a high current leakage under reverse bias: 7.8μA or 0.27mA/cm2 at -4V. The leakage was blamed on the “many defects/dislocations generated in high-indium-content QWs”, as needed for red emission.

At 50A/cm2 injection, the electroluminescence spectra showed a single red peak at 630nm with 62.9nm full-width at half-maximum (FWHM). At lower 10A/cm2 injection, the peak exhibited a shoulder, which the researchers attribute tentatively to “localized states, which originated from the indium phase separation in high-indium-content QWs.” The 630nm wavelength meets the Rec.2020 requirement for red primary color emission.

Between the two current levels there was a large 32nm blue-shift with the increased injection, mainly due to “strong quantum-confined Stark effect (QCSE) and band-filling effect in red InGaN QWs.” Other research on red InGaN tends to see similar shifts. The width of the peak also reduced with increased current due to the emission from localized states saturating. The localized states have more varied emission wavelengths, relative to band-to-band recombination.

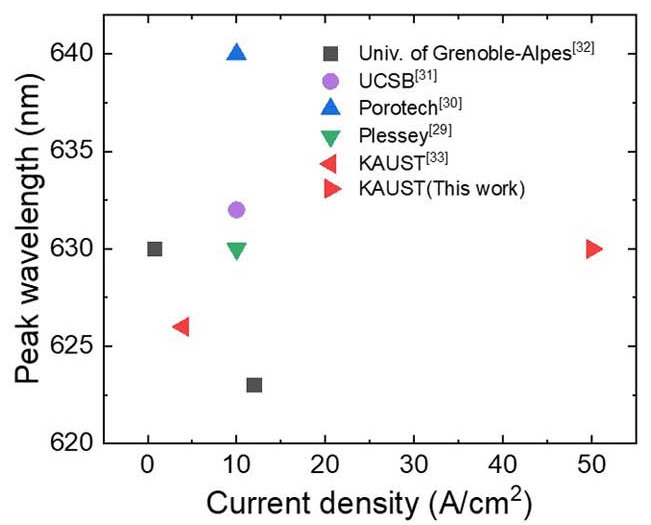

Figure 2: Peak wavelength comparison with other works.

The 50A/cm2 emission at 630nm was at a much higher injection level compared with other attempts at red InGaN μLEDs reported in the literature (Figure 2), which suffer from blue-shift into orange or amber wavelengths.

The external quantum efficiency (EQE) increased up to 40A/cm2, when the increase flattened off, reaching about 0.18% on-wafer at 50A/cm2. The researchers expect that if the measurements had been performed in an integrating sphere, the value would have come in the range 0.3-0.5%. These values are still way below that presently achieved by blue or even green InGaN LEDs.

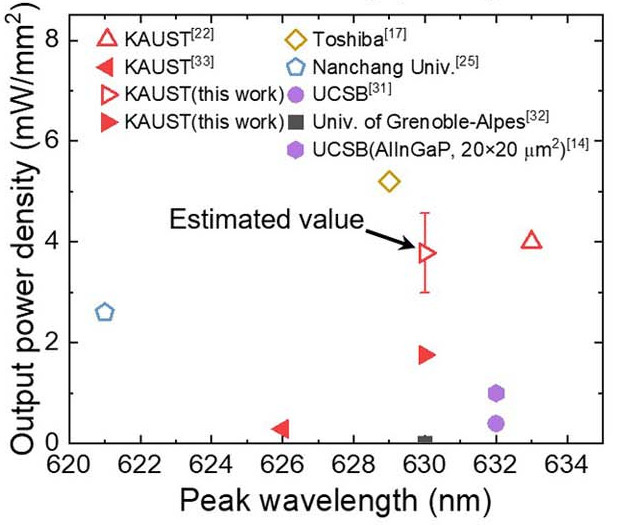

The on-wafer light output power reached 51μW at 50A/cm2. The corresponding output power density was 1.76mW/mm2. The researchers report: “The output power density in this work was the highest compared with other red InGaN μLEDs.” The team also says that their red μLEDs had similar performance to normal-sized red InGaN LEDs.

Figure 3: Output power density comparison with other works. Solid dots on-wafer testing; hollow dots large-sized LEDs in integrating sphere. Also shown, estimate of KAUST value in integrating sphere.

The researchers also compared their work with the output power density achieved in 20μmx20μm AlGaInP LED reports by University of California Santa Barbara (UCSB), along with other reports (Figure 3). The AlGaInP device achieved a 1W/mm2 power density. The UCSB team suggested that this could be increased up to 50% at most by separating the device from the growth wafer.

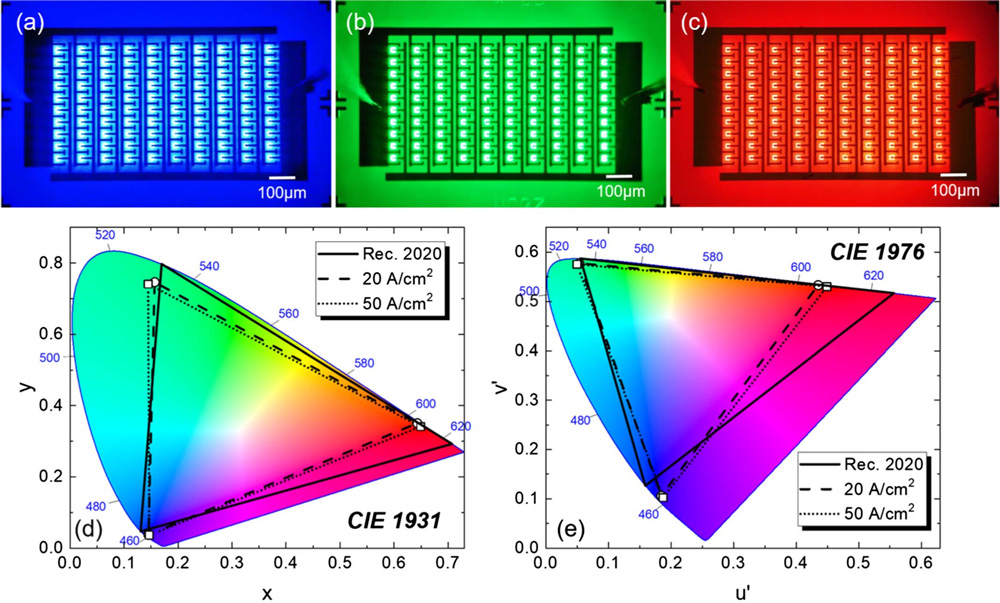

Figure 4: (a)–(c) Electroluminescence images of blue, green and red 10x10 μLED arrays at 20A∕cm2. (d) CIE 1931 and (e) CIE 1976 diagrams blue, green and red 10x10 arrays at 20 and 50A/cm2, along with Rec.2020.

The researchers plotted their RGB device performances on CIE 1931 and 1976 diagrams (Figure 4). At 20A/cm2, the KAUST devices covered 81.5% and 76.2% of the Rec.2020 color space in the CIE 1931 and 1976 diagrams. At 50A/cm2, the corresponding figures were 81.3% and 79.1%. These figures could be improved by using a blue μLED with a wavelength closer to that of the Rec.2020 specification. Such material has already been commercialized.

https://doi.org/10.1364/PRJ.428168

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.